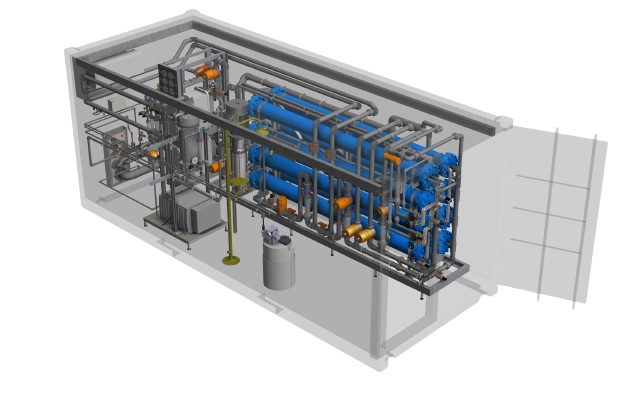

We specialize in providing durable water treatment plants that boast exceptional reliability in operation. Our approach is grounded in extensive expertise in both the theoretical and practical aspects of water treatment. We leverage proven and widely recognized technologies and components to ensure the longevity and effectiveness of our water treatment solutions.

-

Optimized efficiency

-

Extended life-cycle

-

Maximum availability

-

Environmental protection